With the sustainable and sound development of the company as well as joining of ABB Turbocharger service engineers to Gacy Marine Service, the company has been forming a professional service team with fully equipped workshop, to provide Turbocharger services for our valuable worldwide customers.

Team Members for Turbocharger services:

1. Turbocharger service engineers who come from a ABB workshop.

2. Skilled technicians

3. Project coordinators for good and effective communication with ship's crew.

Facilities at workshop for Turbocharger services:

1. Working platform

2. Pretreatment tank

3. Cleaning tank

4. Ash blasting machine

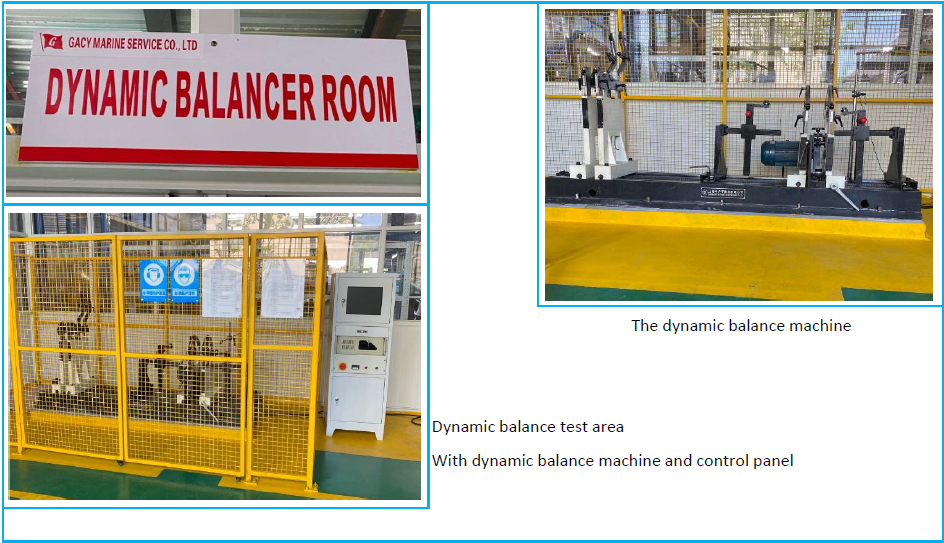

5. Dynamic balance machine

6. Compressed air storage tank

7. Air compressor

8. Cranes/Trolleys

9. Dye penetrant for dye penetration test

10. Welding machine for necessary welding services

| Working Scope/Procedure for Turbocharger Overhaul | ||||||||

| Parts to be overhauled | Working Scope/Procedure | |||||||

| 1. Removal of monitoring & measurement equipment | ||||||||

| Removal and | 2. Removal of filter/silencer if required | |||||||

| reinstallation of | 3. Visual check of filter silencer / suction branch | |||||||

| complete turbocharger | 4. Check T/C foundation for wear | |||||||

| 5. Install same, new or customers replacement turbocharger | ||||||||

| On site | 6. Reinstallation of monitoring & measurement equipment | |||||||

| 7. Removal of filter/silencer if required | ||||||||

| 8.Leave place & turbocharger in clean condition | ||||||||

| Parts to be overhauled | Working Scope/Procedure | |||||||

| 1. Removal of compressor wheel | ||||||||

| 2. Mechanical cleaning of turbine shaft | ||||||||

| Overhaul of Rotor | 3. Visual inspection of compressor wheel | |||||||

| 4. Measurement of shaft dimensions according to working instruction | ||||||||

| At workshop | 5. Dynamic balancing of rotor | |||||||

| 6. Protecting and preparation for shipment | ||||||||

| 1. Measuring and reporting clearance turbine wheel / outlet flange ® | ||||||||

| 2. Removal of air casing | ||||||||

| Overhaul of | 3. Removal of turbine casing | |||||||

| complete turbocharger | 4. Measuring / reporting radial and axial clearances before dismantling | |||||||

| without filter silencer | 5. Dismantling of cartridge | |||||||

| 6. Cleaning and examination of all components | ||||||||

| At workshop | 7. Dynamic balancing of rotor | |||||||

| 8. Reassembly of cartridge group | ||||||||

| 9. Measuring / reporting radial and axial clearances after reassembly | ||||||||

| 10. Reinstallation of air casing and turbine casing | ||||||||

| 11. Measuring and reporting clearance turbine wheel / outlet flange ® | ||||||||

| 12. Protecting and preparation for shipment | ||||||||

| 1. Measuring / reporting radial and axial clearances before dismantling | ||||||||

| 2. Dismantling of cartridge | ||||||||

| Overhaul of | 3. Cleaning and examination of all components | |||||||

| Cartridge Group | 4. Measuring and visual inspection of all parts | |||||||

| 5. Dynamic balancing of rotor | ||||||||

| At workshop | 6. Reassembly of cartridge group | |||||||

| 7. Measuring / reporting radial and axial clearances after reassembly | ||||||||

| 8. Protecting and preparation for shipment | ||||||||

| 1. Dry cleaning of filter silencer | ||||||||

| Silencer and Nozzel | 2. Mechanical cleaning of nozzle ring | |||||||

| Ring Cleaning | 3. Visual check for cracks and erosion | |||||||

| At workshop | 4. Measurement of nozzle ring opening | |||||||

| 5. Document and report measured values | ||||||||

| Removal & inspection of air filter silencer / suction branch | ||||||||

| Removal of wall insert | ||||||||

| Overhaul of | Check axial clearance (A) | |||||||

| complete turbocharger | Clean wall insert, diffuser and compressor casing and check for damage | |||||||

| Removal of gas inlet casing (nozzle ring out) | ||||||||

| On site | Removal / reinstallation of compressor wheel | |||||||

| Removal / installation of axial bearing and sealing disc | ||||||||

| Removal / installation of radial bearings | ||||||||

| Removal / reinstallation of bladed shaft | ||||||||

| Parts to be overhauled | Working Scope/Procedure | |||||||

| Overhaul of | Cleaning and checking of all components | |||||||

| complete turbocharger | Check axial clearance (A) | |||||||

| On site | Connection of monitoring equipment | |||||||

| Leave place & turbocharger in clean condition | ||||||||

| Brand & Model/Type of Turbochargers | ||||||||

| Brand | Model/Type | Brand | Model/Type | |||||

| A130 | TPL65 | |||||||

| A135 | TPL67 | |||||||

| A140 | TPL69 | |||||||

| A145 | TPL71 | |||||||

| A150 | TPL73 | |||||||

| A155 | TPL76 | |||||||

| A160 | TPL77 | |||||||

| A165 | TPL80 | |||||||

| A170 | TPL85 | |||||||

| A175 | VTR201 | |||||||

| A180 | VTR214 | |||||||

| A185 | VTR250 | |||||||

| A190 | VTR251 | |||||||

| ABB(IHI) | A265 | ABB | VTR254 | |||||

| A270 | VTR304 | |||||||

| A275 | VTR354 | |||||||

| A280 | VTR454 | |||||||

| A285 | VTR564 | |||||||

| RH133 | VTR714 | |||||||

| RH143 | VTR566 | |||||||

| RH163 | VTR567 | |||||||

| RH183 | VTR568 | |||||||

| RH203 | VTR454 | |||||||

| TPS44 | VTR564 | |||||||

| TPS48 | VTR714 | |||||||

| TPS50 | AT14 | |||||||

| TPS52 | NR18R | |||||||

| TPS57 | ENPACO - MAN B&W | NR15R | ||||||

| TPS61 | NR24/ R102 | |||||||

| MET26-30SR | TCA66-21394 | |||||||

| MITSUBISHI | MET30SR | STX | NR20/ R248 | |||||

| MET-33SD | NR20 /NR 15 | |||||||

Tel:+86-21-58480296/58480297 Fax:+86-21-50725156 E-mail:gacy@gacymarine.com Address:36 Tanren Road, Pudong New Area, Shanghai 201314

Copyright◎2015 Shanghai Gacy Marine Service Co., Ltd All Rights Reserved

![]()